The Global Plastics Injection Molding Market is poised for substantial growth, with projections indicating an increase from 5.66 million tons in 2023 to 6.95 million tons by 2028, representing a compound annual growth rate (CAGR) of 4.18% within the forecast period of 2023-2028.

Despite experiencing a dip in demand during the COVID-19 pandemic, the injection molding market has shown remarkable resilience and has rebounded to pre-pandemic activity levels.

Key Highlights

The surge in demand for injection molding can be attributed to several key factors, including its expanding use in the automotive sector and the rising demand from the packaging industry. Furthermore, heightened consumer goods and electronics requirements are expected to bolster this demand further.

The transition towards manufacturing lightweight and electrified vehicles, coupled with emerging applications in the healthcare sector, presents lucrative growth opportunities for the plastics injection molding market.

On a global scale, the Asia-Pacific region has emerged as the dominant force in the plastics injection molding market, with significant consumption originating from countries such as China, India, and Japan.

Packaging Segment Takes Center Stage

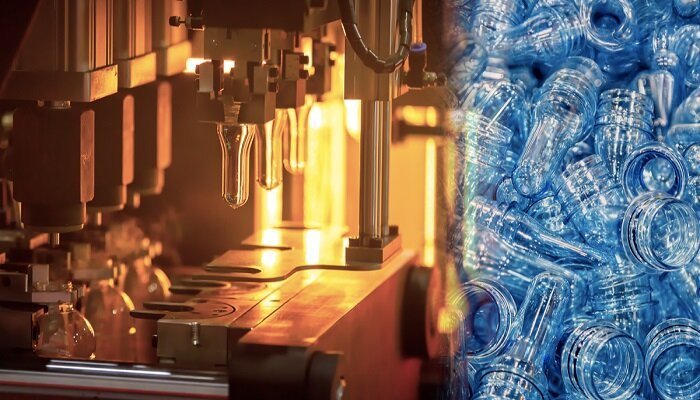

Plastic injection molding provides a plethora of solutions, ranging from high-volume packaging to thin-wall containers and bottle molds. These versatile solutions find extensive applications in the packaging sector across various end-user industries.

In addition to offering adaptable packaging solutions, plastic molding contributes to reducing plastic consumption, making it an ideal choice for economic and ecological considerations.

The global packaging industry is undergoing rapid evolution and expansion. According to a report by the Association for Packaging and Processing Technologies (PMMI), the total value of the global packaging industry reached USD 42.2 billion in 2021.

This growth is primarily driven by factors such as population growth, heightened sustainability concerns, increased disposable income in developing nations, a burgeoning retail sector in emerging economies, and a rising demand for intelligent packaging solutions.

For instance, Japan ranks third globally in the list of largest and fastest-growing e-commerce markets. The country is expected to generate approximately USD 232.20 billion in revenue by 2023, with an average annual growth rate of 11.23% projected between 2023 and 2028. The burgeoning e-commerce sector in Japan is poised to bolster the demand for packaging solutions.

Similarly, the United States boasts a prominent position in the retail industry, with five of the top 10 largest retail companies worldwide headquartered there. According to the Flexible Packaging Association of the United States, flexible packaging holds a substantial 20% share of the market, making it the second-largest packaging segment in the country.

Furthermore, driven by increased consumer demand for packaged food and beverages and the rise of restaurant takeaways in the aftermath of the COVID-19 pandemic, the food and beverage industry’s revenue could reach USD 25 billion by 2025. As of 2021, the industry was valued at approximately USD 21 billion, with food packaging accounting for over half of the total flexible packaging applications.

Given these compelling factors, the demand for plastic injection molding is expected to experience a significant upswing in the packaging segment.

Asia-Pacific Region Maintains Dominance

The Asia-Pacific region is poised to maintain its dominance in the global plastics injection molding market during the forecast period, thanks to the presence of emerging economies such as China, India, Japan, and South Korea.

China, as a leading economy in the Asia-Pacific region, is expected to witness robust growth in its packaging industry, with a projected CAGR of around 6.8% by 2025. This growth is anticipated to drive the nation’s demand for plastic injection molding.

According to China’s Association of Automobile Manufacturers, the country recorded impressive production and sales figures of 27.021 million and 26.864 million vehicles, respectively, representing a 3.4% and 2.1% increase compared to the previous year. The automotive industry’s growing adoption of plastic injection molding is likely to propel demand in this market segment during the forecast period.

Furthermore, the residential construction sector’s expansion in China is expected to further boost the demand for plastic injection molding.