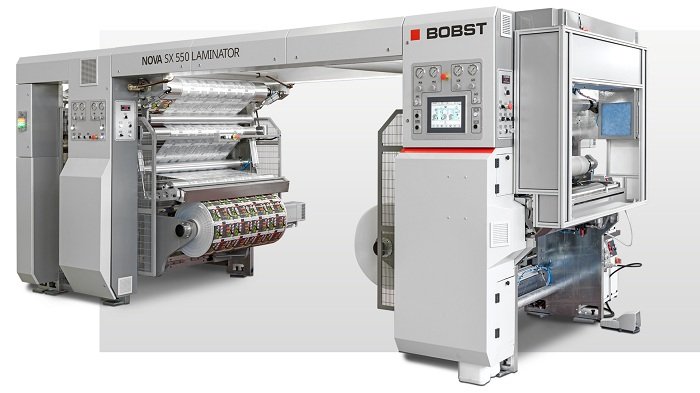

Bobst, a Swiss provider of machinery and services to the packaging industry, has launched Nova SX 550 laminator for brand owners and converters.

The new solventless laminating machine feature a modular design that enables configuration either with transfer rollers or sleeves or monolithic/integral rollers. Designed to deliver cost-effective performance for all production lengths, the laminating machine provides enhanced sustainability and agility for brand owners and converters.

In a press statement, Bobst, said: “We have set out to shape the future of the packaging world by actively driving industry transformation with the digitalisation, connectivity and automation of equipment and services for sustainable production.”

Nova SX 550 laminator capable of handling reels up to 1.5 tonnes

With web widths ranging from 1000mm to 1500mm, the Nova SX 550 laminator has a speed of up to 450 m/min and can handle reels up to 1.5 tonnes.

Additionally, the Nova SX 550 laminator is capable of handling a transfer roller change as well as completes a fully automatic washing cycle in five minutes. The machine also features highly efficient fume exhaust with double fan, a glass closure of the coating unit, an enclosed washing system, and operator protection devices.

Bobst Italia coating and laminating product lines product manager Nanni Bertorelli said: “The machine is industry 4.0-ready for post-processing data.

“There are four NOVA SX 550 machines already sold in Italy, the Middle East, Asia and in the US. This tells us that we’ve hit the mark with a solventless machine that is a good market fit irrespective of local market specificities. We are confident that our innovations will make an impact.”

Recently, Bobst has joined the Circular Economy for Flexible Packaging (CEFLEX) consortium to advance its sustainable flexible packaging efforts in Europe. CEFLEX is a European consortium of companies and associations, which represents the complete value chain of flexible packaging.