Schreiner MediPharm, a Germany-based global provider of innovative functional label solutions for the healthcare industry, debuted sustainable closure seals for pharmaceutical packaging at Pharmapack Paris in January. The ecofriendly closure seals combine high levels of functionality and tamper protection while addressing the industry’s continued push for more sustainable packaging solutions.

Crucially, the new closure seals are ideally adapted to the respective secondary packaging and threat scenarios posed throughout the pharmaceutical supply chain, and do not compromise performance to enhance sustainability. Schreiner MediPharm, in collaboration with the Schreiner ProSecure Competence Center, conducted extensive tests that proved the sustainable seals exhibit comparable performance characteristics as conventional seals pertaining to high transparency, optimal printability, and highly reliable first-opening indication.

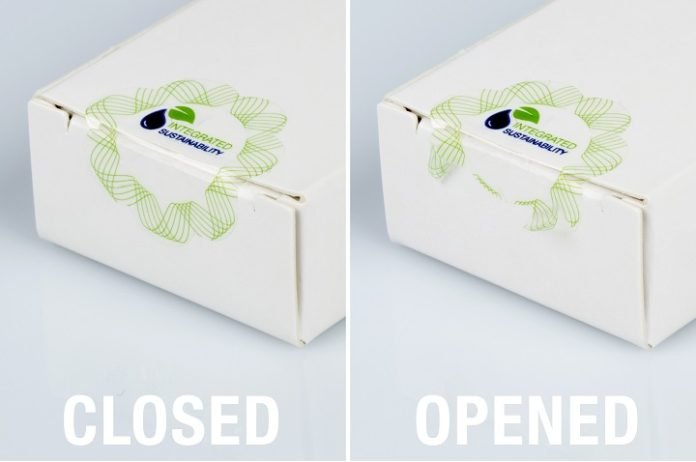

Ever since the EU Falsified Medicines Directive has come into effect, tamper-proof pharmaceutical packaging has been indispensable. Security seals for secondary packaging are a proven means of first-opening indication. In addition, the planned EU Packaging and Packaging Waste Regulation (PPWR) requires waste reductions, reusable packaging, and recycled materials. Aligning with these requirements, Schreiner MediPharm’s closure seal comprises sustainable film material with a recyclate content of up to 90% – far outpacing PPWR’s likely target of 65% post- consumer recycled (PCR) content by 2040.

Switching from conventional to sustainable upper materials made of recyclates leads to a reduction of CO 2 emissions by around 28% at the film level. In the product carbon footprint (PCF) analysis, emission reductions of up to 35% can be achieved. The utilization of green electricity since 2013, as well as the implementation of modern heat pumps in late 2023, help contribute to these encouraging PCF figures.