Leading laser manufacturer Luxinaris looking forward to making a mark with its CO2laser systemsandsourcesin hall 4 booth C91at IPACK-IMA taking place in Milan, Italy, from 3-5 May.Visitors to the Luxinar stand will see a label marking demonstration by a MULTISCAN VS alongside a display of CO2 laser sources from the company’s well-established OEM and SR series.

Luxinar’s CO2 lasers are available at three wavelengths, 10.6, 10.25 and 9.3 microns, and are widely employed within the packaging industry, where applications include cutting, perforating, scribing and marking. Ventilation holes are made in plastic film for packaging fresh produce, lines are scribed to make “easy tear” openings in plastic pouches, and information is marked on cardboard boxes, plastic bottles and painted metal cans.

The 125W MULTISCAN VS is the fastest CO2 laser marker on the market. It can mark stationary or moving products ‘on the fly’ at speeds of up to 1200 characters per second using flexible software; this enables intelligent data to be placed anywhere within the specified scan area. There is also an option to generate and download high quality complex graphics and to produce two-dimensional or traditional bar codes. The laser marker provides perfect line tracking and its compact size and reliability allow easy siting and ‘fit and forget’ low maintenance.

The OEM series of CO2 lasers with a power range up to 1000W represents a compact solution that can be easily integrated into industrial processing production lines; they can be sited in any orientation both with and without covers. The range includes an integrated RF power supply, enabling the laser to produce short optical pulses with high peak power or quasi-CW outputand it can operate safely over a wide range of pulse widths and frequencies including through the acoustic regions and a broad range of coolant temperatures. There is also the option for an absorbing thin film reflector (ATFR) to prevent back reflection issues.

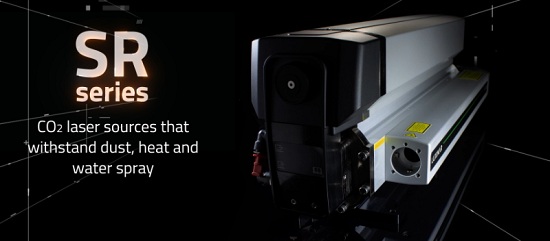

The SR series of sealed CO2 laser sources have a power range up to 250W and a rating of IP66; this means they are ideal for the harshest of industrial environments to ensure a high level of protection against water and dust ingress.The product range is constructed for ease of installation, use and maintenance in laser-based processing machines.Each unit has a compact and lightweight mechanical design with a straightforward DC power supply connection, easy-to-understand control interface and digital diagnostics with enhanced LED. The same output beam position allows for power upgrades with minimal design changes and an integrated RF power supply that is replaceable in the field ensures that production downtime is minimal.

Walter Gensabella, Regional General Manager of Luxinar Italy, explains: “We are excited to be returning to face-to-face exhibiting in Italy with IPACK-IMA.This allows us to easily present and demonstrate our range of CO2 lasers for the packaging industry and the benefits of working with a company that has nearly 25 years of experience in laser technology.”

The LuxinarItaly team will be on hand throughout the exhibition to share their knowledge and provide expert advice on laser technology.

About Luxinar

At Luxinar, we have a singular focus: developing laser technology to enhance our world. Like a laser that channels light into a single, powerful beam, we focus on improving the lives of our customers. This allows us to create solutions to meet every single challenge – from heavy industry to delicate, high precision applications. We support the laser technologies of yesterday, focus on today’s and pioneer those of tomorrow. Luxinarhas been at the forefront of laser technology for over 20 years and is a leading manufacturer of sealed carbon dioxide (CO2) laser sources up to1000W and, more recently, femtosecond laser sources. To date, we have an installed base of over 20000 lasers worldwide in industrial applications environments.