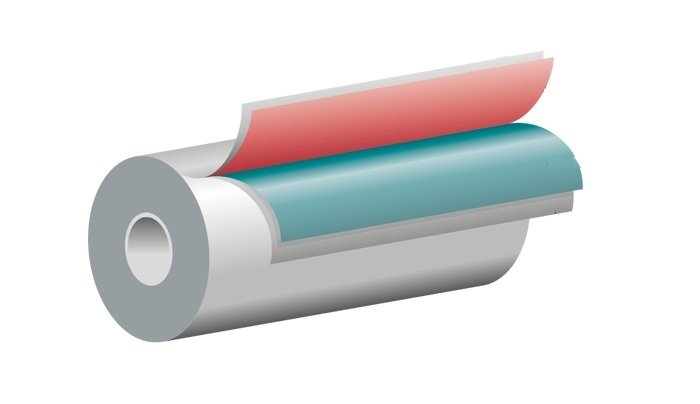

CELAB (Circular Economy for Labels), a consortium representing companies throughout the self-adhesive label supply chain, published a new white paper on challenges and opportunities facing the global recycling of film based silicone liners, a type of layer from which a label is peeled away. The analysis covers the impact of materials used in the production of film based silicone liners, the feasibility of recycling processes, and end uses for their recycled resin.

Key findings, based on non-proprietary information collected by CELAB from raw materials producers, recycling companies, and industry organizations, include:

- While filmic materials are used for release liners most frequently in North America, their growth in label applications is higher in all regions compared to paper based release liners.

- The main challenges to the recycling process for film based silicone release liners are related to the amount of silicone coating on the release liner and potential contamination of the recycle stream.

The amount of silicone on a release liner is impacted by how they are manufactured – specifically, during the silicone coating process. - While the most common approach is to recycle film based silicone release liners back into the production cycle for identical products, it is possible they can be used to create the raw materials needed for alternative production processes, cutting down landfill waste and lowering the demand for virgin materials feedstocks.

“The publication of this white paper supports CELAB’s mission to advance a more sustainable, circular economy for the self-adhesive industry by facilitating the sharing of insights and best practices from a global and regional perspective,” said Alex Knott, Senior Scientist at The Dow Chemical Company and head of CELAB’s Global Technical Workstream. “Its findings offer a comprehensive look at the entire value chain for film based silicone release liners, the use of which is growing worldwide. The information gathered here will better equip our industry and its partners to continue increasing access to recycling.”